- |

- |

- |

- |

Company Name

Rinnai Corporation

Head office

2-26, Fukuzumi-cho, Nakagawa-ku, Nagoya, Japan, 454-802

TEL:+81-52-361-8211

Incorporated

September 1, 1920

Established

September 2, 1950

President

Hiroyasu Naito

Paid-in capital

¥ 6,484,410 thousand

Number of Group companies

46 companies

Stock listing

Tokyo and Nagoya Stock Exchange

Securities Code : 5947

Number of employees

10,386【consolidate】

3,722【Rinnai Corporation】

(As of March 31, 2011)

Sales and profit【Consolidated】

Net sales

: ¥344.3 billion

Operation income

: ¥40.6 billion

Net sales

: ¥42.4 billion

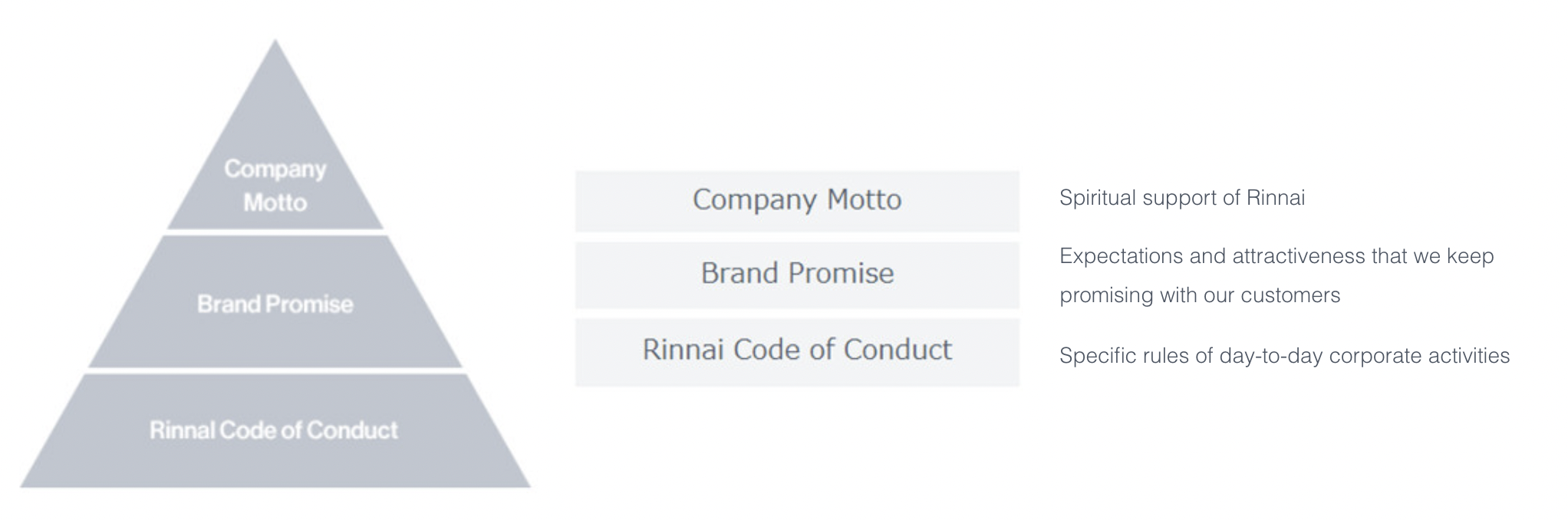

Schematic Diagram of Corporate Philosophy

Company Motto

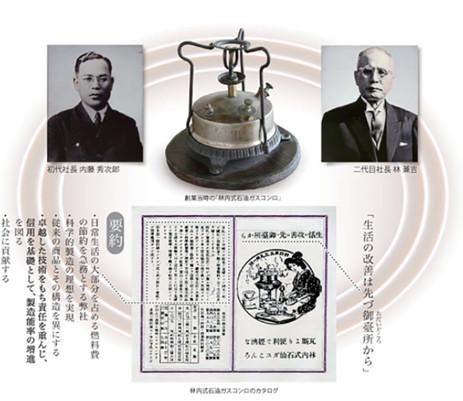

The Birth of Rinnai

Rinnai uses reliable technologies to create "heat and lifestyles" while embracing the spirit of its foundation

One November day in 1918, Hidejiro Naito stood mesmerized in front of a shop making imagawayaki, a traditional Japanese bun usually filled with adzuki bean paste.

He was intrigued by the blue flame that came from the imported oil-burning cooking stove used to cook the imagawayaki. Keen to try his hand at making a similar stove, Hidejiro convinced the shop owner to part with the stove. Using it as a model, Hidejiro subsequently developed a petroleum-fuelled stove, heralding the origin of the business we know today.

Two years later, in 1920, Hidejiro left his job at Nagoya Gas (currently Toho Gas Co., Ltd.). Together with Kanekichi Hayashi, a childhood friend who lived in the same dormitory, they established Rinnai & Co., the forerunner of today's Rinnai Corporation. The company name was coined from characters in the two men's last names ("Rin" is another way of reading Hayashi, and "Nai" comes from "Naito").

Thus began nearly a century of developing the latest heat-energy appliances. Over the years, Rinnai's products slowly transformed Japanese lifestyles as the nation continued on its path to modernization.

From its origins through to the present day, Rinnai has been guided by its Corporate Mission, which is "to use heat to provide society with comfortable lifestyles."

The ethos of contributing to society—evident in the early catalog for Rinnai's original, petroleum-fuelled stove—has endured unchanged through to the present day.

Logo Rinnai

The contemporary sans-serif font has a robust form and is somewhat heavier than before.

The rounded design has a gentle, friendly, human-oriented feel. Overall, the logo conveys

The Rinnai brand's promise to create a healthier way of living for tomorrow's world.

Brand Promise

Creating a healthier way of living

We look past the short term, seeing the world from a long-term perspective.

We consider not only humanity, but the entire global environment, fostering harmony.

We do all we can to make our customers smile and keep them healthy. We are honest and never lie.

We continually take on new challenges with an open mind, never limiting ourselves to conventional thinking or customs.

We create not only functionality and performance, but also meaning and significance.

These are our promises to our customers and to society as a whole. This is what we mean when we say, "Creating a healthier way of living."

Brand Movie

Founded in 1920, Rinnai & Co. first manufactured and sold pressurized oil stoves. By the late 1920s it had already

established itself as a trustworthy manufacturer of gas tabletop stoves, gas ovens, gas heaters, and gas hot-water

units.

1920

The company is incorporated as Rinnai & Co. by founders Hidejiro Naito and Kanekichi Hayashi.

1923

Deliveries of gas appliances, including tabletop stoves, ranges, gas ovens, and water heaters, to Japanese gas

utilities nationwide, as well as exports, begin.

1938

Manufacturing of aircraft parts takes place with the factory coming under military supervision.

1947

Production of gas and kerosene appliances resumes at the rebuilt Head Office factory.

1950

The company is reorganized as a joint stock company and renamed Rinnai Seisakusho.

1954

The Tokyo Sales Office (now the Kanto Branch) opens.

1957

The Aichi Factory (now the Chubu Branch) opens.

The company forms a technology tie-up with German company Schwank GmbH to manufacture and sell gas infrared

burners and to develop heaters and cooking appliances that use them.

Development of Schwank infrared gas heater (Japan's first).

1959

Start mass production of ceramic plate (Japan's first).

1960

The lnba Factory (later the Asahi Factory) opens.

Received the Ota Award from the Japan Gas Association for the Schwank gas burner.

1961

The Fukuoka Sales Office (now the Kyushu Branch) opens.

1963

The Sendai Satelite Office (now the Tohoku Branch)opens.

Grill mounted on gas stoves (Industry's first).

1964

The Oguchi Factory opens.

1967

The Technology Development Center opens.

1969

The Nagoya Sales Office (now the Chubu Branch) opens.

Development of FF gas hot-air heaters (Japan's first).

1970

Rinnai Taiwan Corporation is established.

1971

The name changes to Rinnai Corporation.

Development of gas high-speed convection oven (Japan's first).

RB Controls Co., Ltd., is established.

Rinnai Australia Pty. Ltd. is established.

1972

Received the Ota Award from the Japan Gas Association for the gas high-speed convection oven.

1973

Rinnai (Malaysia) Sdn. Bhd. is established.

Development of ceramic burner for grill (Japan's first).

1974

Rinnai Korea Corporation is established.

Rinnai America Corporation is established.

1975

Rinnai New Zealand Ltd. is established.

Received the Ota Award from the Japan Gas Association for the gas pressure cookers.

Equipamentos NGK-Rinnai Ltda. is established.

1976

Rinnai Industries (UK), Ltd. is established.

Development of drum-type gas clothes dryer (Japan's first).

1978

Gas high-speed range with microcomputer control (Industry's first).

1979

The company is listed on the Second Section of the Nagoya Stock Exchange.

Development of gas high-speed range with microwave oven (Japan's first).

Rinnai Precision Co., Ltd. is established

Development of gas rice cooker with electric jar (Japan's first).

The Seto Factory opens.

1980

Received the Ota Award from the Japan Gas Association for the gas rice cooker with electric jar

Built-in hob with grill and oven (Japan's first)

Development of gas fan heaters (Japan's first)

1981

Japan Ceramics Co., Ltd. is established.

Business partnership with lsomura Kiki (now Rinnai Technica Co., Ltd.)

1982

The company is listed on the Second Section of the Tokyo Stock Exchange.

1983

The company is listed on the First Section of the Tokyo Stock Exchange and Nagoya Stock Exchange.

1984

Gas stove with push ignition system (Industry's first).

1988

P.T. Rinnai Indonesia is established.

The Hong Kong Representative Office opens.

1990

The Tsukuba Research Center (now Tsukuba Training Center) opens.

Gas fan heaters with air purifiers (Industry's first).

Rinnai (Thailand) Co., Ltd. is established.

Development of inner flame stove burner (Industry's first).

Noto Tech Co., Ltd. is established.

1991

Rinnai Singapore Pte. Ltd. is established.

α-KAMADO rice cooker wins G-Design Award.

1993

Shanghai Rinnai Co., Ltd. is established.

1995

The company receives ISO 9001 certification for all domestic factories.

1996

Rinnai Holdings (Pacific) Pte Ltd. is established in Singapore.

The company receives Testing Facility Acceptance from International Approval Services (IAS).

1997

Commercialisation of absorption-type household gas air conditioners (World's first).

Voice remote control with auto-stop function for water heaters (Industry's first).

1998

Rinnai Hong Kong Ltd. is established.

Rinnai Vietnam Co., Ltd. is established.

1999

Business partnership with Gastar Co., Ltd.

Commercialisation of condensing gas water heaters for domestic use (Japan's first).

RG Co., Ltd. is established.

Development of the Super Eco Burner, a high-efficiency burner for stoves (Industry's first).

2003

The company receives ISO 14001 certification for all domestic factories.

Received the Energy Conservation Grand Prize (Chairman's Prize) from the Energy Conservation Center for a

glass-top stove with inner flame burners.

Plasmacluster ions in gas appliances (Industry's first).

2004

Guangzhou Rinnai Gas and Electric Appliance Co., Ltd. is established.

2006

RBS Thermo Technology Co., Ltd. is established.

2007

Good Design Award 2007 for built-in hobs.

2008

Rinnai Italia S.r.l. is established.

Commercialisation of a built-in dishwasher with a baking soda cleaning model (World's first).

The Integrated Logistics Center opens.

Received the 2008 Good Design Award for seven products: built-in hobs, dishwashers and fan heaters.

Rinnai gas tankless water heater receives the Super Nova Star Award (an energy-saving award) from the Alliance

to Save Energy in the United States.

2009

Rinnai Canada Holdings Ltd. is established.

Received the 2009 Good Design Award for six products: built-in stoves, drop-in stoves and condensing hot-water

heaters.

2010

Commercialisation of a household hybrid water heater combining a heat pump and a high-efficiency condensing

water heater (World's first).

Received the Technology Grand Prize from the Japan Gas Association for the DELICIA GRiLLER and DELICIA Udea

built- in hobs.

2011

Received the 2011 Good Design Award for five products: built-in stoves, built-in dishwashers, remote controls

for water heater and commercial kitchen units.

2012

Received the 2012 Good Design Award for five products: built-in stoves, remote controls for water heater,

water

heater, and the ECO ONE hybrid water heater system.

2013

The Akatsuki Factory opens.

Received the 2013 Good Design Award for the built in hob DELICIA.

2014

Received the 2014 Good Design Award for five products: built-in stoves, built-in dishwasher, remote controls

for

floor heating.

2015

Brivis Climate Systems Pty Ltd in Australia is acquired.

Received the 2015 Good Design Award for the hybrid water heater system ECO ONE.

The Dubai Representative Office opens.

2016

Development of a DELICIA app with auto cooking support function.

2017

Received the Energy Conservation Grand Prize (Chairman's Prize of the Energy Conservation Centre) for the

third-generation hybrid water heating system "ECO ONE".

Received the Good Design Best 100 in 2017 Award for the Domino gas built-in hob "G:101".

2018

Received the Gold Award at the 2018 Aichi Environmental Awards for the hybrid water heating system "ECO ONE".

Received the 2018 Good Design Award for the gas built-in hob RB-2CG and RB-3CG for the ASEAN market.

2019

Our brand promise is established, and the Rinnai logo is updated.

Received the "Minister of the Environment Award" of the COOL CHOICE LEADERS AWARD 2018 for the hybrid water

heating system "ECO ONE".

Received the Good Design Best 100 in 2019 Award for the Domino IH Cooking Heater.

2020

Received the Red Dot Design Award 2020 for the G-LINE series of Domino built-in hobs.

Received the Japan Childcare Support Award 2020 for the gas clothes dryer.

Received the 2020 Good Design Award for the microbubble bath unit.

Quality is our destiney

Rinnai Corporation has adopted "Quality is our destiny" as its basic quality philisophy and strives to infuse the idea of "Customer first", "Product safety" and "Legal compliance" throughout Rinnai group, and stabilize the culture of product safety.

Manufacturing

Since our founding, we have used heat to provide people with healthy and comfortable lives. However, even a small defect in heating equipment can cause a major accident.

As a comprehensive manufacturer of heat and energy equipment, we have rigorously practiced "quality-oriented manufacturing" at our R&D and production sites, placing top priority on the safety and security of our customers. Committed to engaging in the best manufacturing practices, we focus on the following three things.

Self-sufficiency

We emphasize in-house production technologies in order to improve quality.

Integrated production

We integrate all processes—from design to processing, assembly, inspection, and shipping—in order to ensure high quality.

Mechanisms to support safety and security

Reflecting our belief that the best manufacturing derives from employee skills and optimal environments, we strive to improve education and work spaces.

Pursuing "self-sufficiency" to improve quality

At Rinnai, we are committed to handling all stages independently, including the design of processing technologies necessary for production. We make our own dedicated equipment and tools to ensure reliable manufacture of safe and high-quality products. We believe this is key to raising our manufacturing standards.

Moreover, self-sufficiency enables us to accumulate and pass on technologies and skills, leading to creation of better products.

1. Prototypes

We draw on the skills of artisans to ensure greatest accuracy of prototype design. We also actively work on new prototyping methods to provide a smooth transition to mass production.

2. Molds

We are constantly pursuing better mold technologies, which are very challenging, and using the results of these activities to reduce costs.

3. Equipment

We are committed to a wide range of in-house automation technologies, from processing of parts to shipping of final products, and the competitiveness of our manufacturing sites is increasing as a result.

4. Software

We are developing original software that fully addresses the requirements of rapidly changing manufacturing sites, so we can quickly respond to requests from each site.

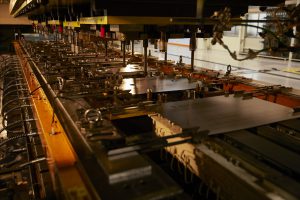

Integrated production system ensure high quality

We make high-quality products because we adopt an integrated production system at our own factories. This covers all processes, from processing to assembly, inspection, packaging, and shipping.

We also respond flexibly to market needs because we can handle mixed production of multiple items, and we can flexibly and quickly make the required products only when needed. This includes our ability to handle express shipments and large-volume orders.

Parts processing

Metal pressing process to transform materials into shapes. Suitable for multiple-product, small-lot

manufacturing.

Welding process to join parts together. Here, we use robots and other automated operations to ensure

consistent quality.

Painting and enameling to make components visually appealing. Here, we conduct strict visual quality

checks.

Assembly

A large number of parts are fastened with screws to complete the product.

Many error prevention FP devices are installed.

Inspection

Rigorously conducted by qualified inspectors using automated inspection equipment.

All items are inspected to ensure high levels of quality and safety.

Packaging & shipping

Packaging process to ensure safe delivery of products.

This process is strictly controlled and covers not only products but also visual quality of outer packaging.

Logistics

Speedy delivery using QR code management and inspection system.

Aiming for zero defects across entire Rinnai Group

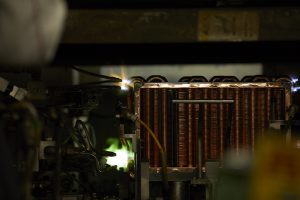

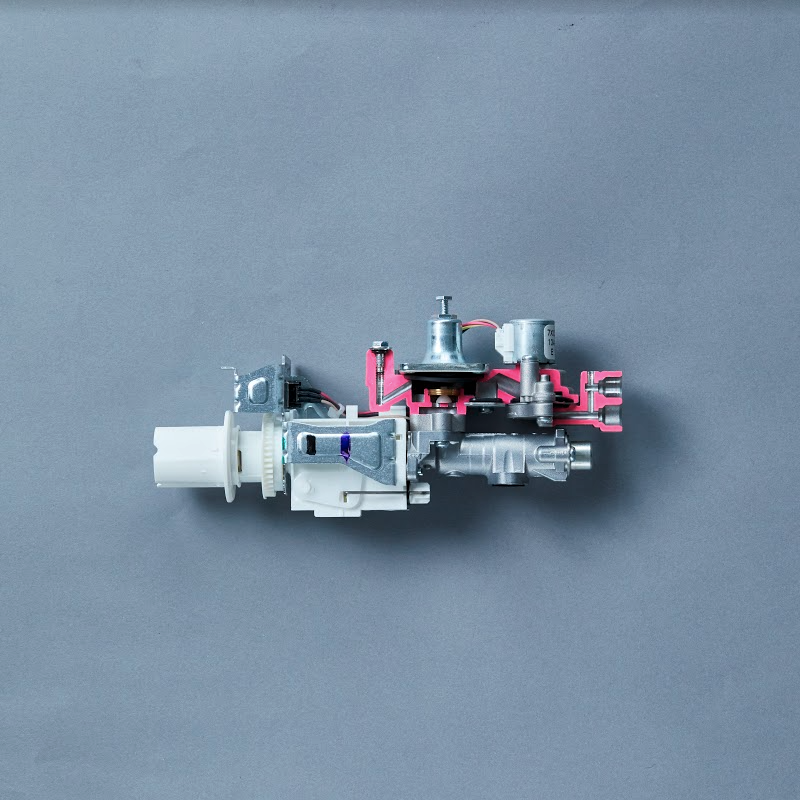

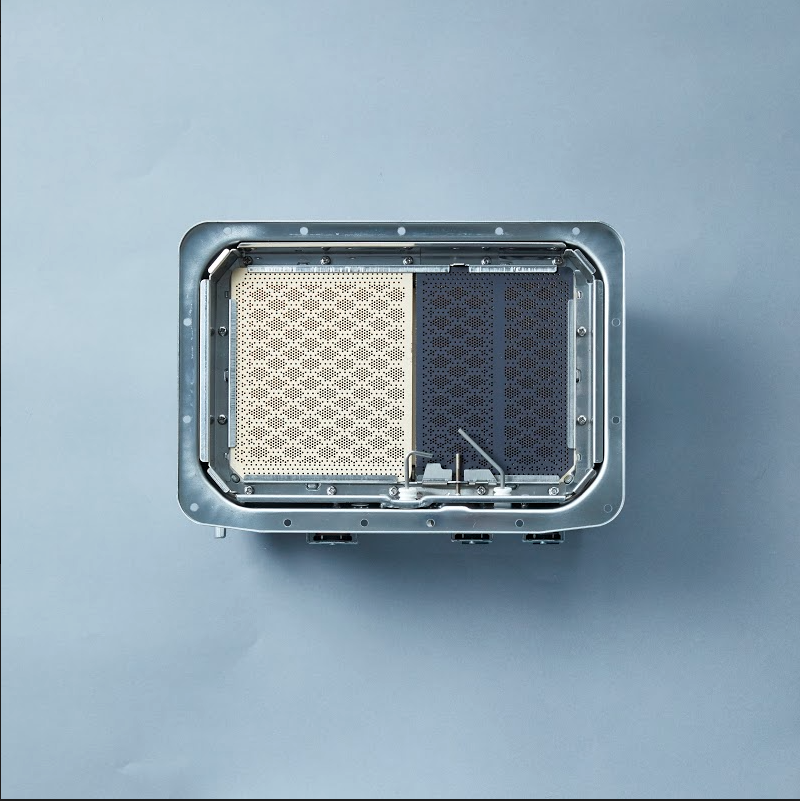

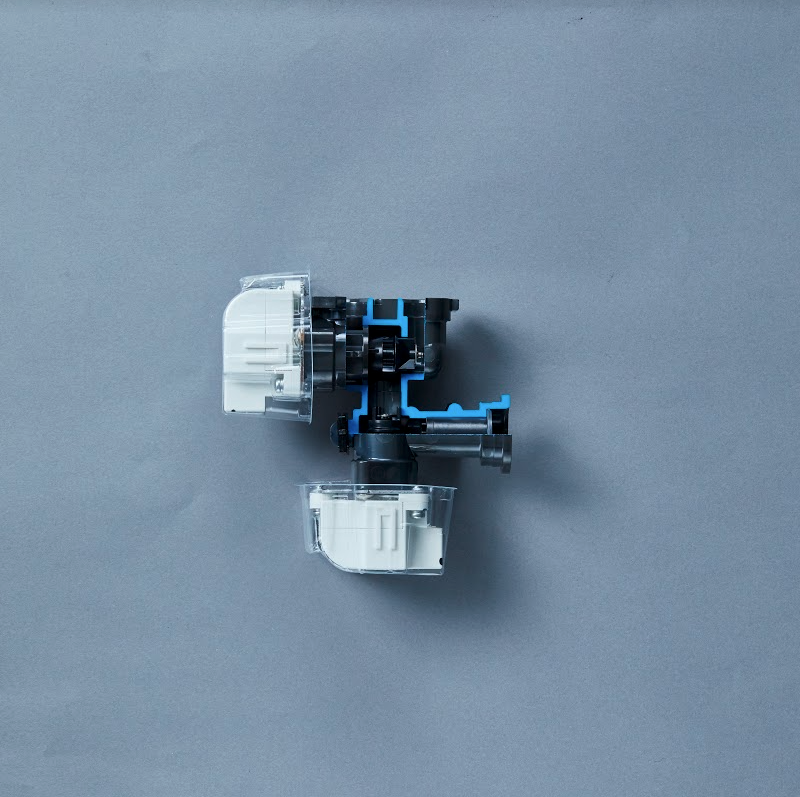

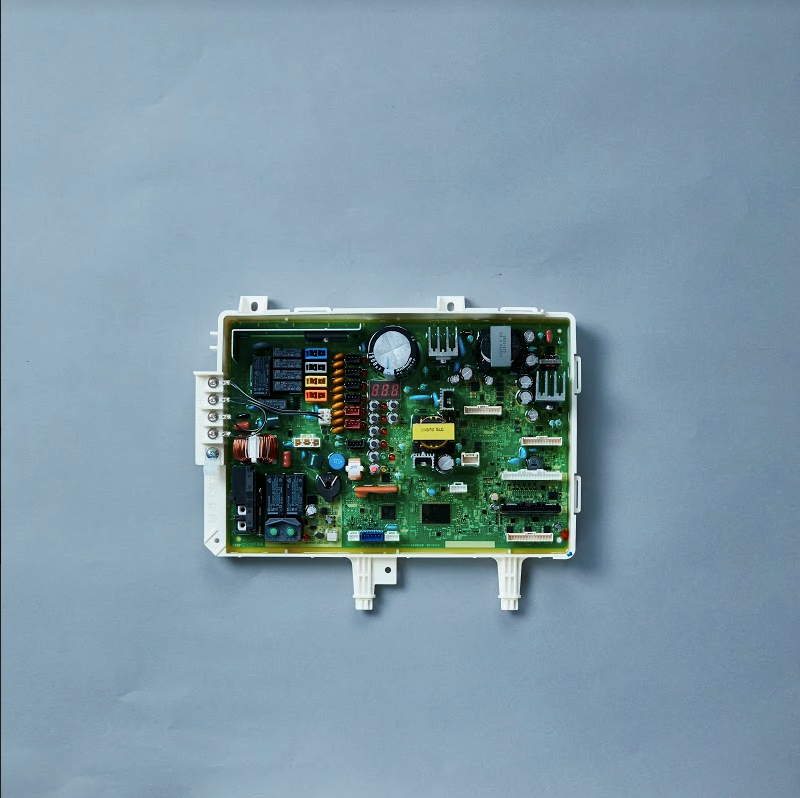

Important control-relared parts, such as gas control units, are developed in-house and manufactured by Rinnai Group companies.

Aiming for zero defects across entire Rinnai Group, we work as one to manufacture safe and secure products.

Gas valve

Gas valve

Ceramic plate

Ceramic plate

Water value

Water value

Electronic unit

Electronic unit